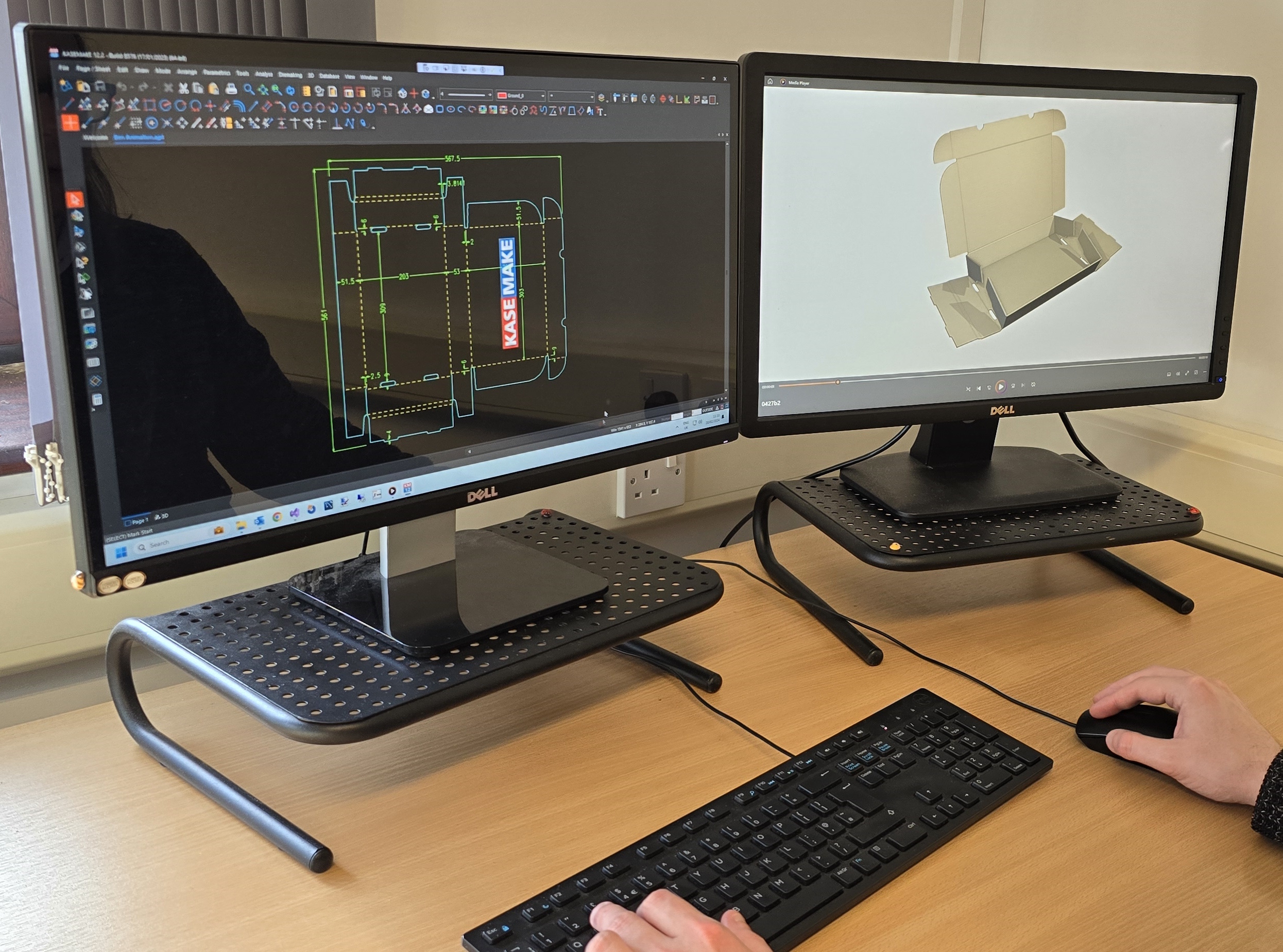

KASEMAKE and K-CUT Vision

Designers and machine operators around the world use KASEMAKE to get the best results from their ideas and materials

As well as its design capability KASEMAKE Software enables you to get the best out of your DYSS Digital Cutter.

KASEMAKE is compatible with most output equipment: from printers, pen plotters, sample tables, digital cutters, lasers and CNC routers.

Enhanced functionality is available for control of KM and DYSS cutting machines as well as machines from other manufacturers.

With KASEMAKE you have, at your fingertips, the result of almost 40 years of experience working with the industry. We have produced one of the most complete collections of specialised design and cutting tools on the market.

You will find that KASEMAKE’s speed, ease of use, functionality and built-in design templates make it essential for your business.

Router Offset Tool

You can use KASEMAKE to quickly prepare jobs for cutting using a router bit rather than a knife.

The router offset tool automatically compensates for the diameter of the router bit making sure that

the piece you are cutting is the correct size.

The router offset tool is also capable of generating multiple passes to cut tough,

dense materials in smaller passes to avoid straining the router spindle or damaging the bit.

The tool has a further option to automatically add holding tabs to avoid small pieces moving once cut.

A finishing pass can also be added to give optimum edge-quality on the final cut.

Pocketing Tool

When you want to mill out flat areas in a material (e.g. when engraving text) you can use KASEMAKE’s pocketing tool.

Applied to closed boundaries, this clever tool works out the most efficient paths to mill out each area with minimal lifting of the router bit.

Automated Production, Conveying and Sheet-Feeding

DYSS Digital cutters can be specified with an optional conveyorised belt to move media along, allowing you to handle longer-than-table or repeat jobs;

or sheet-feeders to automatically load and cut sheets of material.

With KASEMAKE you can control conveyor movement and also split long jobs into cut-area length sections.

As a result, you can continuously cut roll-material or enable automatic production when your table has a suitable feeder.

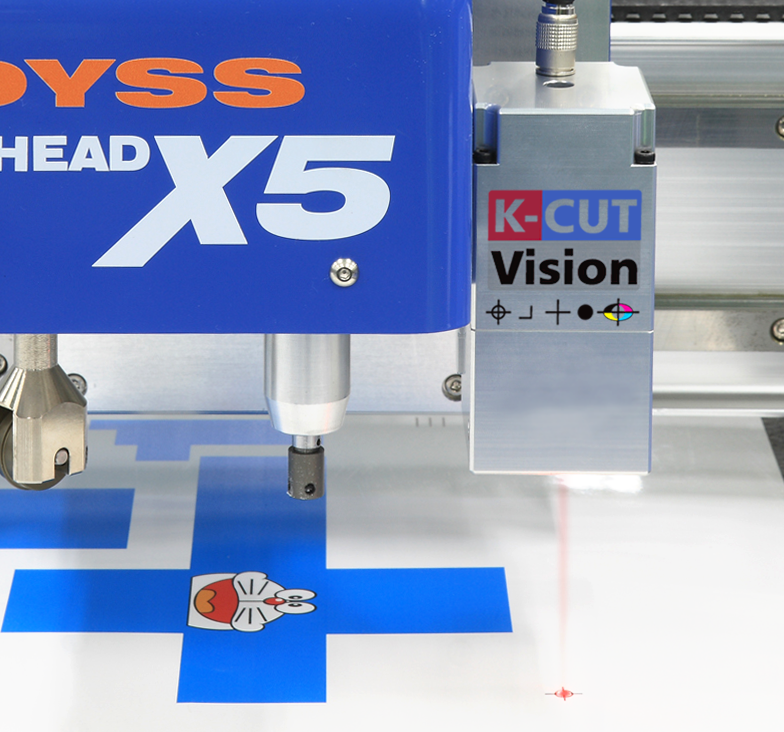

The K-CUT Vision system is an option for your DYSS to enable cut-to-register functionality.

A high resolution colour camera mounted to the tool-head automatically identifies registration marks that have been added to the artwork. Intelligent and flexible, the system can quickly recognise even badly printed or damaged marks.

The camera can also detect the edges of media to cut plain or print face down sheets accurately.

The vision software compares the marks or edges found by the camera with their expected positions. Using this information, the software adjusts the cutting paths to compensate for any inaccuracies such as rotation, stretch and skew.

K-CUT Vision cuts the job precisely, even when the material is badly positioned or the print is significantly distorted.

Ask AG/CAD About KASEMAKE and K-CUT Vision

One of our product specialists will get back to you ASAP (Typically within one working day)